Hammers look simple at first glance, but each type is built with a clear purpose in mind. The shape of the head, the weight, and even the handle length all affect how the tool behaves when it strikes a surface. Using the wrong hammer can bend fasteners, damage materials, or slow a job down.

Using the right one makes the work cleaner, safer, and far less frustrating. This guide walks through the most common hammer types, explains what they are meant for, and helps you understand which one belongs in your hand for a given task.

What Is a Hammer and How Does It Work?

A hammer is a striking tool that transfers force from your swing into a small contact area on the head, which is why it can drive a nail, shape metal, crack masonry, or set hardware with just a few hits.

The head’s weight does most of the work once it’s moving, and the handle length acts like a lever that helps build speed. Face shape matters too: a flat face spreads force for driving, a rounded face concentrates it for shaping, and softer faces reduce marring on finished surfaces.

Grip and swing matter as much as the tool. Choking up gives control for light taps, while holding near the end of the handle gives power for heavier blows. The “right” hammer is the one that matches the material, the fastener, and the amount of force you actually need.

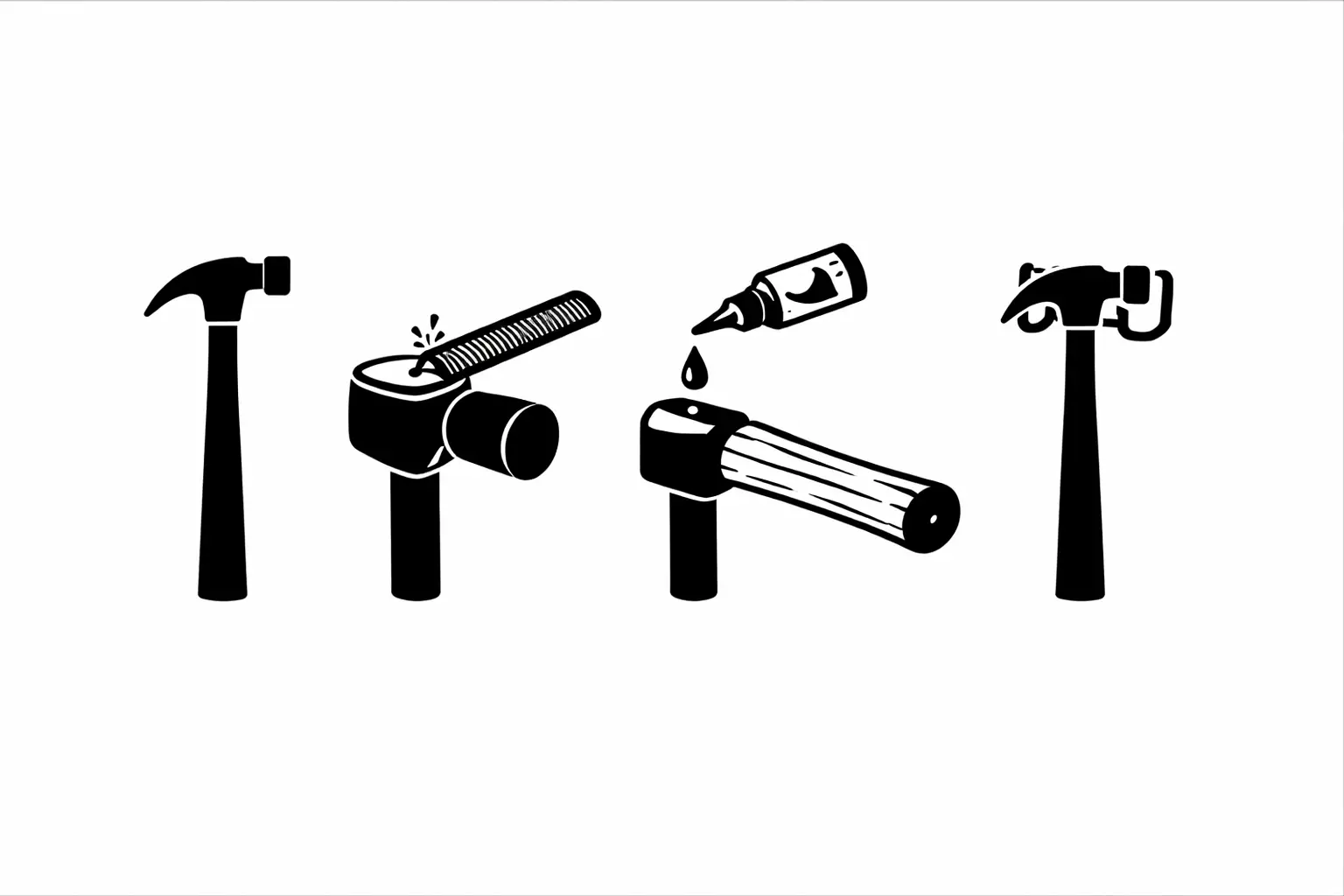

Most Common Types of Hammers

Most jobs only need one thing from a hammer: the right kind of force in the right way. Some hammers are built to drive fasteners cleanly, others to shape metal, and some to move heavy material that won’t respond to lighter tools. Knowing the basic categories makes buying a hammer easy and avoids future damage.

Claw Hammers (Carpenter’s Hammers)

Claw hammers are the standard pick for home repairs and light carpentry. They combine a flat striking face with a curved claw that pulls nails and handles light prying. Weight and face style matter more than brand when choosing a hammer.

Best uses

- Driving and removing nails in wood

- Hanging fixtures, shelves, and wall hardware

- Small repairs and trim work

Pros

- Versatile for everyday tasks

- Easy to control for most users

- Nail-pulling claw reduces the need for extra tools

Cons

- Not ideal for heavy framing

- Can damage finished wood if misused

- Limited usefulness on metal or masonry

Framing Hammers for Heavy-Duty Work

Framing hammers are built for speed and power on construction sites. They hit harder, swing longer, and grip nail heads better than standard claw hammers.

Best uses

- Framing walls, floors, and roofs

- Driving large nails into structural lumber

- Prying apart boards during rough work

Pros

- Delivers strong blows with fewer swings

- Waffle faces reduce slipping

- Straighter claws handle tough prying

Cons

- Heavy weight causes fatigue

- Leaves marks on visible wood

- Overkill for household repairs

Ball Peen Hammer (Machinist Hammer) Explained

Ball peen hammers are designed for metal rather than wood. The rounded end shapes metal, while the flat face handles punches and controlled strikes.

Best uses

- Shaping and peening metal

- Setting rivets and pins

- Striking metal chisels or punches

Pros

- Precise control on metal surfaces

- Durable hardened steel head

- Useful for automotive and shop work

Cons

- Not suited for nails or wood

- Can dent softer materials easily

- Limited use outside metalwork

Mallet Hammers

Mallets are about controlled force without surface damage. They come in rubber, wood, plastic, and composite styles, each suited to different materials.

Best uses

- Assembling furniture

- Tapping parts into alignment

- Woodworking with chisels

Pros

- Reduces surface marks

- Absorbs shock well

- Safer for delicate parts

Cons

- Lacks power for hard fasteners

- Soft heads wear over time

- Not suitable for demolition

Sledgehammer

Sledgehammers exist for one reason: force. They are heavy, long-handled tools meant to move or break things that lighter hammers cannot.

Best uses

- Breaking concrete or stone

- Driving stakes and posts

- Heavy demolition work

Pros

- Extremely powerful strikes

- Simple, durable design

- Effective on stubborn materials

Cons

- Requires space to swing

- Higher injury risk if mishandled

- Too heavy for precision work

Specialty Types of Hammers You Should Know About

Specialty hammers solve specific problems that common hammers handle poorly. They help you work cleaner on a certain material, in tight spaces, or when surface damage is not acceptable.

Masonry Hammer (Brick Hammer)

A masonry hammer is made for brick, block, and stone work. One end is a flat face for striking, while the other end is usually a chisel-shaped blade for scoring and splitting masonry. It’s handy when you need quick shaping on site and don’t want to haul out a saw for every small cut.

Best uses

- Scoring a brick before snapping it on a line

- Knocking off small sections, corners, or high spots on blocks

- Tapping the brick into level while setting the mortar

- Cleaning up hardened mortar lumps on brick faces, with light, controlled hits

Pros

- Built-in chisel end saves tool swaps

- Works well for quick sizing and small adjustments

- Stands up to abrasive masonry work

Cons

- Not for finish carpentry or nails

- Can chip brick faces if you rush the strike

- Chisel edge needs upkeep to stay useful

Roofing Hammer

A roofing hammer is designed around shingles, nails, and speed. Many have a hatchet-style blade for cutting shingles, plus a magnetized nail starter to set a roofing nail one-handed. Some versions also include a gauge for consistent shingle spacing.

Best uses

- Cutting asphalt shingles for hips, valleys, and edges

- Starting roofing nails when your other hand is holding material

- Fast nailing on small roofing repairs

- Trimming underlayment and flashing materials in a pinch

Pros

- Nail starter helps on steep pitches

- Blade reduces the need for a separate shingle knife for quick cuts

- Made for repeated nailing without feeling clumsy

Cons

- Too specialized for most indoor jobs

- Blade can be hazardous in a tool belt if not sheathed

- Not a clean-cutting tool for thick materials

Tack Hammer

A tack hammer is light and slim, built for small nails and short swings. It often has one magnetic face to hold a tack in place so you can start it with one hand. Upholstery work is where it shines.

Best uses

- Setting upholstery tacks without crushing fabric

- Hanging light trim pieces where a large hammer would slip

- Installing small brads in thin wood

- Reaching into corners where a bigger head cannot fit

Pros

- Great control with tiny fasteners

- Magnetic face makes starts easier

- Less chance of denting nearby surfaces

Cons

- Too light for most carpentry

- Bends larger nails instead of driving them

- Not built for prying

Dead Blow Hammer

A dead blow hammer is meant to hit without bounce. It usually has a plastic or rubber outer shell and a hollow head filled with shot, which keeps energy moving forward instead of springing back. That makes it a go-to in assembly, automotive work, and stubborn-fit parts.

Best uses

- Seating bearings, bushings, and press-fit parts with less rebound

- Persuading stuck wheels, rotors, or housings without marring metal

- Aligning parts during assembly when you need firm taps

- Working on jigs, fixtures, or machine setups where bounce causes mis-hits

Pros

- Minimal rebound helps accuracy

- Less surface damage than steel

- Safer when you’re striking near your hands or delicate parts

Cons

- The head can split after heavy abuse

- Not suited for sharp edges or cutting strikes

- Bulkier than a standard hammer in tight spots

Planishing Hammer

A planishing hammer is for metal shaping, not brute force. It’s used to smooth and refine sheet metal after it’s been formed, often against a dolly or stake. The faces are polished, so they don’t leave deep marks.

Best uses

- Smoothing dents and ripples in sheet metal panels

- Refining curves after rough shaping

- Working on automotive body patches for a better fit

- Finishing light-gauge metal work where surface quality matters

Pros

- Helps create smooth surfaces with controlled blows

- Polished faces reduce unwanted marks

- Useful for fine metal finishing work

Cons

- Takes practice to avoid stretching metal

- Not useful on wood, masonry, or nails

- Needs clean, polished faces to avoid imprinting defects

Power Hammer

A power hammer is a machine, not a handheld tool. It delivers repeated blows at high force for forging and shaping metal, using dies that form the work as it’s struck. You’ll find these in blacksmith shops and fabrication spaces where hand hammering would be too slow or too inconsistent.

Best uses

- Drawing out steel for forging work

- Shaping stock quickly with repeatable strikes

- Forming parts with dies for consistent results

- Doing high-volume forging tasks where hand work would be exhausting

Pros

- Moves metal fast with consistent blows

- Reduces strain compared to constant hand hammering

- Useful for larger stock that is difficult to handle by hand

Cons

- Expensive and space-hungry

- Requires training and safety controls

- Not practical for typical home projects

Hammer Maintenance and Care Tips

A hammer stays safe and predictable when the head is secure, the striking faces are in good shape, and the handle is sound. Most failures happen slowly, then all at once, so quick checks and basic cleanup go a long way. Treat every hammer like a striking tool only, unless it’s clearly built for prying or cutting.

- Check the head before each session. If it wiggles, stop. A loose head can fly off and injure someone.

- Inspect the handle for cracks and splinters. Sand small splinters, then seal wood handles with a light coat of oil. Replace any handle with serious cracks.

- Keep faces clean. Wipe off sap, grease, and grit so the face doesn’t slip or grind debris into your work.

- Dress damaged steel faces. If a steel face mushrooms or chips, smooth it with a file or grinder so fragments don’t break off during strikes. Wear eye protection.

- Protect finished faces. Planishing hammers and other polished faces should stay free of nicks. Store them so they don’t bang into other tools.

- Replace worn soft faces. Rubber, plastic, and dead blow faces can split or deform. Swap the caps or replace the hammer once the face is compromised.

- Keep wood handles from drying out. If a wooden handle looks dry, rub in a small amount of boiled linseed oil and wipe off the excess.

- Avoid using hammers as pry bars. It bends claws, loosens heads, and damages handles. Use a pry bar when the job is really prying.

- Store hammers dry. Rust on a face can stain wood, and corrosion around the eye can loosen the head over time.

- Use the right hammer for the strike. Don’t hit hardened steel with hardened steel unless the tool is meant for it, since chips can fly. Use brass, rubber, or dead blow tools when surface damage is a concern.

FAQ

Most framers settle between 20–22 oz with longer handles to balance driving force against wrist and elbow fatigue during sustained nailing cycles.

The milled face concentrates pressure at raised points, preventing nail slip but compressing wood fibers, which leaves visible dimples on contact.

Use a ball peen when striking hardened punches or chisels, since its flat face and steel hardness reduce chipping and uncontrolled energy transfer.

Repeated high-energy strikes can crack the shell or rupture internal shot chambers, reducing rebound control and shifting the hammer’s balance during impact.

Yes. Steel-on-steel impacts can cause edge spalling. A softer striking face or sacrificial striker is safer for wedges and chisels.

Wooden mallets compress slightly on impact, delivering controlled force without damaging chisel handles or transmitting sharp shock into the user’s hand.

Moisture loss in wooden handles shrinks the eye fit, allowing gradual head movement that worsens under repeated high-force swings.

This content is generated by AI, reviewed by our editorial team, and features products that have been thoroughly evaluated and chosen.